Features

Cultivation

Competing and winning as a micro cultivator

April 18, 2022 By Jarred Marsh and George Dickinson

Photo: UF/IFAS Communications

Photo: UF/IFAS Communications A licensed micro cultivator is limited to a canopy size of 200 square metres, and so, the best way for micro cultivators to improve profitability is to increase their yields and improve product quality. Harvesting, drying, curing and preserving cannabis is just as important as growing it. Micro processors should commit themselves to the highest standards as differentiating factors.

Our advice would be to really hone in on craft cultivation which would include the use of proper, clean virus-free genetics with maximum yields per square foot and offer hand-trimmed quality in a well-preserved state for the end customer.

The importance of genetics

The quality of your final product begins with the quality of your starting material. Some viruses (like Hop Latent Viroid) can spread unknowingly throughout your crop and wreak havoc when it is too late. Whether you start from seed, clone or tissue culture plantlet, it is important to work with your labs and vendors to ensure that your starting material is virus and pathogen free.

Selecting your strain is equally important. When selecting a strain, choose strains that are in demand and work with your type of growing environment. Selecting a strain that doesn’t work for your environment is the easiest way to leave untapped potential on the table.

Maximizing square footage

Once you’ve selected the genetics that work for you and your market, it’s time to get the most of what that plant can offer.

As a rule of thumb approximately 20-25 per cent of an indoor grow facility is dedicated to mothers, cloning and vegetative growth. That would be equivalent to 400-500 square feet, which represents a cost center in your operation.

Utilizing a ready-to-flower plant (or “teen”) which shows up at your facility ready to place into your flowering rooms, can allow you to repurpose your veg and mother space into flowering space. On top of the added square footage you would gain, you would also be eliminating the vegetation time that will provide an additional 1-1.5 crop rotations per year in that space.

Maximizing yields

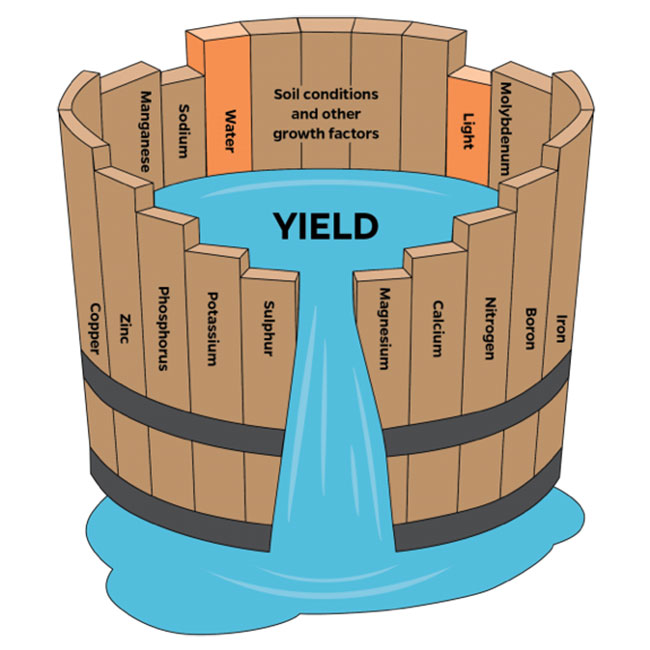

Liebig’s Law of the Minimum is a principle developed in agricultural science in 1840 which still rings true today and is still used by growers worldwide. It states that if one growth factor is deficient then plant growth will be limited, even if all other vital factors are adequate. Above is a good illustration using a barrel with staves. Each stave of the barrel represents a single growth factor.

Leveraging the appropriate tools and collecting valuable data is essential. There are various sensors and tools on the market which can record real-time and historical data. These sensors can tell us what is happening in the climate at any point in time and can help identify microclimates in your grow room.

Substrate sensors allow you to see what is happening in the root zone in real time and fix potential issues long before we see these issues manifest in the plants. The phrase “crop steering” is gaining popularity these days, with the proper real time data we can now steer the plants one way or another depending on the growers objectives.

Processing and preserving

Over time, improperly stored cannabis can degrade and an updated lab test could indicate that your product has decreased in value as a result.

A drop in moisture content results is a drop in weight. A five per cent drop in moisture content can result in a six-pound loss on a 1,000-pound batch. This is an easy opportunity to improve consistency, quality and revenue per batch. Use an airtight storage vessel along with a humidity control pack to stabilize the moisture content in your flower.

This not only maintains the value of your product but in more mature markets, longer cured flowers at the proper water activity (moisture level) can fetch a higher price tag.

Minimizing costs

Lowering your overall costs is a key to success in cannabis cultivation. Energy and labour are typically the two biggest costs to produce cannabis.

The use of high quality LED lighting with the proper spectrum helps tremendously as they not only use less electricity, but they give off about 25 per cent less heat which lowers cooling costs drastically. Using circulation fans that are more efficient at moving air is another good practice. They typically run all day and night inside grow rooms. Over the course of a year, that’s a lot of electricity.

For your labour, you can utilize low cost things like simple conveyors to move trays of plants around the facility or a simple greenhouse cart to move plants from room to room.

Trimming is extremely labour intensive. Consider hand trimming the top colas and machine trimming the middle and bottom buds.

Jarred Marsh is head of Accounts & Strategy at GrowHaus Supply Co.

George Dickinson is an Equipment and Cultivation specialist at GrowHaus Supply Co.

Print this page