Features

Opinion

Cultivation

Management

Facility Tours: Calgary LPs shine in the Wild West

OGEN and Distinkt Cannabis’ common thread is unparalleled cultivation methods

September 11, 2023 By Haley Nagasaki

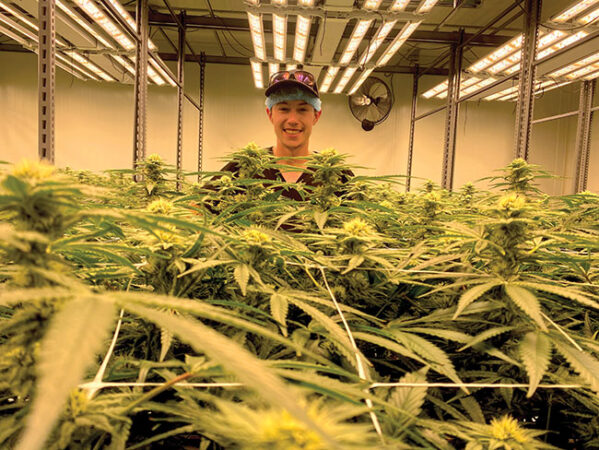

OGEN cultivation team: Justin Creencia, Carson Stewart, Baker. Photo: Luke Dickson, brand manager, OGEN

OGEN cultivation team: Justin Creencia, Carson Stewart, Baker. Photo: Luke Dickson, brand manager, OGEN As the cannabis industry continues to progress, either holding fast as a drought-resistant cacti or behaving more like a voracious Venus flytrap, it’s important to celebrate the producers who are adapting to the shifting tides.

This past July, Grow Opportunity ventured to wild rose country and toured two very different LPs – OGEN and Distinkt – showcasing the superior cultivation practices they hold in common.

The Calgary-based producers, while friendly competitors, have entirely different strategies spanning grow technique, marketing tactics, staffing and fields of influence. OGEN’s team of leaders, with their scientifically driven backgrounds coupled with their passion for growth, development and the industry at large, informs their culture-forward approach to operations. While Distinkt, now also expanding into psychedelics, prefers more of the legacy ethos when coming to market. Both approaches hold water, so to speak, though one in rock wool and the other in coco.

A cultivation room in bloom at OGEN. Photo: Luke Dickson, brand manager, OGEN

Getting to kn-OGEN

OGEN obtained their cultivation license in 2018 and underwent an expansion phase to increase their operations’ capacity. December 2019, they achieved occupancy and by mid 2020 they expanded their workforce from a dozen to over one hundred individuals, ramping up production and offering specially curated cultivars to the recreational market. Currently, OGEN distributes their products in Alberta, Manitoba, Saskatchewan, Ontario, New Brunswick and Newfoundland, while working to establish presence in provinces in which they are not yet active.

The LP also recently received its extraction license and formed a partnership with Simply Solventless, allowing them to offer a diverse range of products combining craft flower with Solventless’ bubble hash and live rosin. In general, the LP is keen to explore mutually beneficial partnerships catering to quality and consumer taste that is the hallmark of their brand.

The faces behind the flower are led by three passionate individuals who are invested and proficient in their areas of expertise: cultivation manager Justin “JC” Creencia, post cultivation manager Carson Stewart, and irrigation and environmental manager Baker. Joining the OGEN team near the beginning as technicians, these three have grown in their proficiency as leaders of an equally passionate cultivating team now tending the quality of cannabis they grow today.

Having experienced the technician’s highs and lows, the three managers work not only to maintain and increase the quality of OGEN’s flower but to increase the quality of life for their staff – the entire team prides themselves on a rotating phenohunt series within an indoor cultivation space of approximately 55,000 sq ft.

Their delicious, best-selling strain Peach Chauffeur #15 checks a lot of boxes and has been very well received in market. Velvet Apples #12 is another favourite, balancing both flavour and potency. While the guys at OGEN recognize the reality that “you can hurt yourself with too much variety,” says operations manager James Brophy, still the team is always on the lookout for something new with bag appeal.

OGEN also emphasizes smart marketing and a culture-forward approach. The thriving Calgary tourism industry enables the LP to position itself as a must-visit destination for local budtenders, enthusiasts and curious tourists with the goal of ending stigma against both the plant and the industry.

“I don’t think you need to be an expert to get excited about seeing how something is made,” says Luke Dickson, OGEN’s brand manager. “It is a staple part of some vacations to check out local breweries or wineries, like Heineken or Steam Whistle, without having to be a buff. That’s why we offer open tours that can be booked by anyone of legal age in Alberta. It helps to remove stigma and break down the barriers of education,” he says.

Dosi-GMO #6 cultivar. Photo: Luke Dickson, brand manager

Original techniques

With each province that Grow Opportunity visits, seeking cannabis stories to share nationwide, comes the search for differentiation. Whether it’s Manitoba’s intense UV and cool evenings, the water quality of the Pacific Northwest, Quebec’s affordable electricity or the agricultural fecundity of the Niagara region, each province boasts a unique cultivation quality regardless of whether crops are grown indoors or out.

For Alberta, cannabis growers take full advantage of the region’s drier climate and better humidity control compared to the regions with excess moisture. Post-harvest and drying processes can make or break a crop, so it’s possible that Alberta has a leg up in this department. At their indoor facility, the entire cultivation team takes pride in their work and their approach to testing, experimentation and hands on learning while incorporating lessons learned into their operations and business values.

“It’s so easy to cut corners in a lot of small ways, which leads to quality ultimately being compromised,” says Stewart. “We are always watching to make sure our crops are not dying a death by 1,000 cuts. Each area of production has to hold themselves to an extremely high standard.”

The cultivation process also consists of multiple harvests each week and the careful handling of plants to prevent quality degradation. During harvest, “each plant is carefully chopped, extricated from its neighbours and draped over racks for storage,” says Brophy. Rolling harvested plants down the halls on racks rather than carrying them by hand or dropping them into totes helps mitigate trichome damage. Before, during and after harvest, the sanitation team also plays a vital role at the LP by maintaining a sterile work environment. “They do a great job; this room is spotless when they’re done,” says Brophy. “All of this debris will be gone and that’s something that I think people don’t understand – every piece of plant material has to exit this room – it’s a daunting task when you first look at it. That amount of sanitation really is the cornerstone of everything that we do here.”

The sanitation team also helps during post-harvest in the curing process. Taking only a couple hours in the morning to complete a harvest and sanitize a room, the LP has quickly streamlined operations by employing knowledgeable people with good chemistry. “We’re familiar with how testing and experimentation goes on,” says Brophy. “Our QA has a master of chemistry. They’ve helped run all of those changes and experiments for us to really dial in consistency and quality; that’s the main driver for us.”

Though the managers had no previous cannabis experience, and each began with an entry-level position, they’ve all grown in the same way the company has – through research and hands on experience. “These guys have so much passion that they bring to the table,” says Dickson, “and none of this would have happened if they weren’t like that,” which is a fact that helps bolster the producer’s unique imprint on the Canadian cannabis space.

Distinkt Cannabis, left to right: Jacob Mauer, Bailey Osberg, Landon Grams, Joenica Garcia, Jacob D’eath

Demystifying DISTINKT

Mark Corrigan, founder and president of Distinkt Cannabis and previous golf pro founded the company in 2017 and received their production license in early 2021. With a total of 22 employees all who wear many hats, and a second location Distinkt 2 coming online in the coming months, the Calgary-based LP is poised for expansion when the time is right. Having a lean, versatile team “is the way to get through this nightmare price reduction, compression, but at some point, prices will have to go up,” says Corrigan. While the LP is looking to expand into psychedelics, mainly psilocybin production, they heed caution knowing “there’s no reason to be the first one to the party,” says Corrigan, who intends on waiting until he feels the market is viable.

The same is to be said with the live rosin category, though the entire rosin market in Alberta is only valued at $600,000. Distinkt will wait for an increase in consumer demand before exerting further time and resources into rosin production. Currently, the provinces that carry their products include Alberta, Yukon, Saskatchewan, Manitoba and Ontario.

The producer also grows their own phenohunted genetics and some of their own breeding as well. Corrigan sees this production technique as one of the markers for success, because “anything you bring to market, no one else is going to have.”

A tour of the LP revealed primarily the cultivation of Monaco Octane and Lemon Razz – a solid cultivar that continues to come in at 26-30 per cent THC and over three per cent terpenes.

Jacob “JD” D’eath, head of cultivation at Distinkt Cannabis, amidst a room in flower.

DISTINKT cultivation

Head of cultivation, Jacob “JD” D’eath studied cannabis production at Olds College and was previously employed as a grower at OGEN. “Before that I grew black market and before that I worked at a garden centre,” he says. “One day I found a seed in my weed, so I bought a grow light and it snowballed from there.”

Within six grow rooms, D’eath experiments regularly, specifically surrounding defoliation variations and high-stress training of the canopy to increase both yield and quality. In a room of Lemon Razz one week into flower, D’eath demonstrates the training method he’s employed by bending and almost breaking the stem, which stunts the plants and makes the tissue harden up to create a more even canopy.

Corrigan also explains the motive behind the facility’s construction, previously a meat packing plant, by taking “black market sized rooms and growing commercially,” he says. “The biggest room is 850 sq ft – we keep it tight and controllable so we can have consistent product.”

They’re also working with a known breeder called TK, experimenting with different cuts to see about bringing them to market in partnership. “Some people can grow but they don’t have the bandwidth for sales, boards and marketing,” says Corrigan. “TK has a good name in the black market and from a breeding perspective, it’s something we’d look at bringing in.”

The facility uses a semi-automatic fertigation system now with valves that can be opened and closed using apps connected to the teams’ smart phones. Each of the rooms also has its own HVAC system so that if something goes down, it only affects one room.

They’ve been fortunate to keep down pest pressure, “but you know,” says Corrigan, “everyone’s got their own challenges. I think what’s kept us alive is we’re small enough to keep nimble, our operating expenses aren’t crazy, and we still produce consistent product and we continue to tell our story.”

Distinkt 2 is already built out, “and we’ll turn the machine on when we see a larger market,” Corrigan says, leaning into an extraction lab mainly for rosin and additional square footage for the cultivation of psilocybin or other types of fungus or cacti. Distinkt houses a driven team full of proponents of the therapeutic benefits of psychedelic therapy, but still, “we’re not there yet,” he says.

Corrigan looks forward to opening the second facility, located 15 minutes away, that will be EUGMP-certified and seamlessly operated by a crew of 50. Until then, the national company has capitalized off their learning experiences, taking pride in what they’ve so far accomplished. “We’re proud of what we do here,” says Corrigan; “we’re proud of making great products.”

Print this page